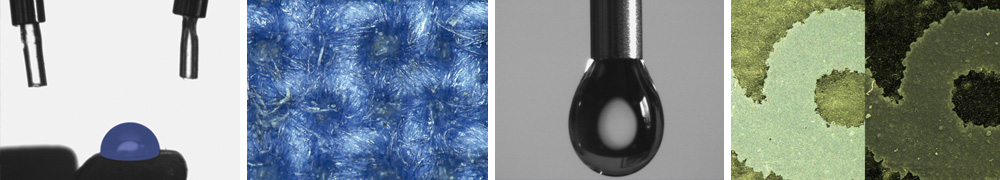

Easy to design, difficult to customize, material properties tailored to the specific use, the most varied shaping processes AND usually hard to coat – this pretty much sums up the properties of plastic products.

Due to their nonpolar molecular structure, many polymers have to be activated or sometimes cleaned to enable decorations or labels to bond to the surface. As an nonpartisan engineer, I can help to select the process that best meets the demands of your application and can best be integrated into your manufacturing workflow. This includes supporting you when examining and evaluating the respective experiments and trials as well as during the implementation phase.

Are you considering using a new material and would like a feasibility analysis to indicate whether the material can be properly coated? Let me take care of it for you while you deal with your day-to-day operations.

One of your polymer surface projects seems to be faltering and you are looking for a boost from an external source to get it moving again? I would be happy to hear from you. Having someone from “outside” look at the issue and examine the current status is the first step to finding and implementing a solution.

The process chain has not changed, but the paint is coming off or bonding fails!? I can analyze the delamination for you. It is essential to look at the process chain on site to find the aspect causing the problem. If additional analytical testing is required, I will arrange for it and act as the nonpartisan link between you and the testing lab.